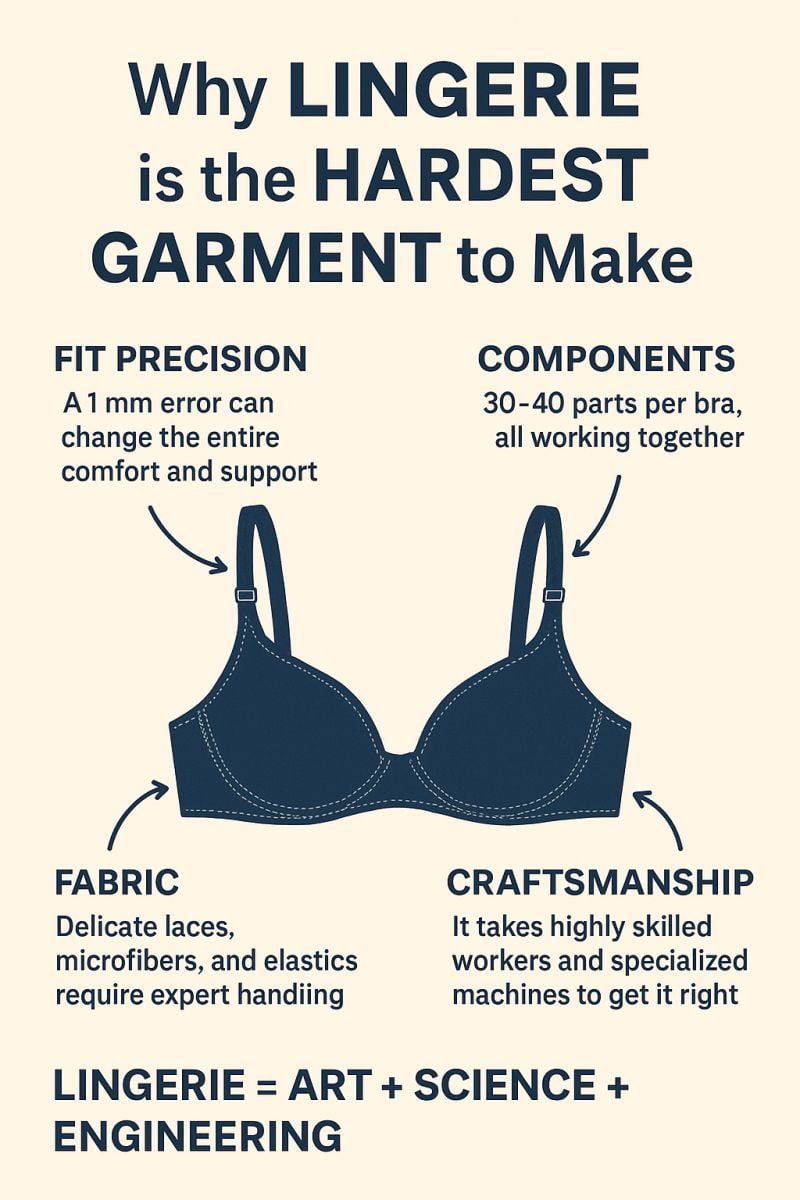

Why Lingerie Is the Hardest Garment to Manufacture

When most people think of lingerie, they imagine delicate lace, satin, or sheer fabrics stitched into beautiful designs. But behind the elegance lies one of the most technically complex challenges in the apparel industry. Lingerie manufacturing is not simply about “sewing fabric” — it’s about engineering garments that combine comfort, functionality, and beauty.

The first challenge is fit precision. Unlike a T-shirt that can stretch to adjust, lingerie has to fit the body with millimeter accuracy. A 1 mm error in cutting or stitching can change how the bra feels — making the difference between supportive and uncomfortable.

Next comes component complexity. An average bra is made up of 30–40 individual components — cups, wires, elastics, straps, hooks, and more. Every single piece must be assembled in perfect harmony. If even one element is slightly off, the entire product fails to deliver comfort and support.

Then there’s fabric behavior. Lingerie fabrics are some of the trickiest to work with: delicate lace that can tear easily, microfibers that stretch in unpredictable ways, and elastics that require careful tension control. They demand specialized machinery and skilled hands that know how to tame them.

Finally, lingerie requires craftsmanship. Unlike mass-market garments, lingerie cannot be rushed. Each stitch, seam, and finish needs precision. This is why many lingerie factories rely on artisans who spend years honing their craft.

Put simply, lingerie is where art, science, and engineering meet. It’s a product that looks effortless when worn, yet behind the scenes requires unmatched expertise.

✨ And that’s exactly why global brands trust specialized lingerie manufacturers — because in lingerie, every single detail matters.

click and follow Indiaherald WhatsApp channel

click and follow Indiaherald WhatsApp channel